Homeownership involves quite a bit more maintenance and upkeep than many realize, and knowing what to do and how to prioritize a myriad of tasks over time can seem overwhelming. Below is a list of maintenance suggestions relevant to each titled section, and we hope you find this guide useful!

EXTERIOR: The exterior components act as the “skin” of the structure and a first line of defense against the elements, and all exterior areas and components should be continually monitored and well maintained to ensure the structure is well protected and safe. This includes (in part) maintaining all vegetation at least 1-2 ft from the house exterior, repairing any damage to siding, trim, fascia, soffit and flashing, cleaning moss, algae or other vegetation growth, monitoring the base of cladding and deck/porch posts, ensuring that soil grading is positive (sloped away from the foundation), maintaining exterior caulk, sealant, paint and stain, keeping wood piles at least 30 ft from any structure, sealing any exterior cracks and crevices, repairing any damaged masonry, protecting any exposed, bare or deteriorated wood, and addressing unwanted pest activity.

ROOF & PENETRATIONS: The roof is a crucial first line of defense for the structure and should be maintained in the best condition possible, which includes (in part) continual monitoring of the roof covering for signs of damage, periodic cleaning of gutters, debris and vegetation growth, extension of downspouts across lower roof surfaces and at least 5 ft from basements or crawlspaces or 2 ft from slabs, sealing of any exposed fasteners or deteriorated sealant/flashing, and securing of any loose roof, vent or rain spouting fasteners. If not already present, gutter guards would ideally be installed to prevent accumulation of vegetation and other debris that could hinder proper drainage, and installation of heat cable along eaves is often beneficial for preventing ice damming.

GARAGE: Cracking in garage slabs (concrete floors) is common due to shrinkage or possible heaving, and any cracks should be well sealed and periodically monitored, whether present now or in the future. Attached garages should contain suitable fire separation material, such as 5/8-inch type “X” drywall, between the garage interior and adjoining living spaces, and garage man doors leading to the house interior should be solid and self-closing (fully fire rated) to prevent the spread of fire and potentially harmful exhaust gases (including carbon monoxide) that more frequently occur in garages. Working photo-electric “red eye” safety sensors should be present within 6 inches of the ground at the base of overhead and mechanical garage door tracks, and garage door openers should be connected to dedicated receptacles rather than extension cords. Although not required, any exterior man doors serving garages should be equipped with deadbolt locks to improve security.

FIREPLACES & STOVES: All fireplaces or stoves should be operated with care and safety and continually maintained as needed, and all chimneys should be periodically monitored for signs of damage or buildup. Hearth extensions in front of wood-burning fireplaces should be at least 16-20 inches deep, depending on the size of the fireplace opening, to prevent a potential fire hazard, and the firebox (interior) of a fireplace should be kept clean from excessive ash, soot/creosote and corrosion buildup. For wood-burning or vented units with a damper, the damper and its control should be in good working order to ensure safe exhaust of combustion gases and smoke and to properly regulate draft. Masonry chimneys should be equipped with a flue liner to safely carry exhaust outdoors and a rain cap to prevent unwanted water, debris or vermin intrusion that could lead to possible damage or obstruction. Metal chimneys should be generally free of rust and an appropriate, listed type for the appliance served.

STEPS & RAILINGS: Handrails should exist where there are more than 3 steps (counting landings) and should be secure, graspable, continuous, located 34-38 inches above the front nosing of stair treads, and equipped with vertical balusters (spindles) along open sides that are spaced closely enough together that a 4-3/8” sphere cannot pass between them. Likewise, guardrails should exist at landings 30 inches or higher and should be secure, at least 36 inches (3 ft) high, and equipped with vertical balusters spaced no farther than 4 inches apart. Guardrail barriers should also be vertical, not horizontal, as horizontal balustrades are climbable for small children. The minimum recommended height at stairways is 6’-8” (although lower heights are common in older homes), and stair treads and risers should vary in depth or height no more than 3/8-inch to prevent a potential trip hazard. Stair risers over 4 inches in height should also be closed where there are more than 3 steps, and open risers are very common at deck, porch and basement stairways. Doors should also not open above stairs unless a minimum 3’ x 3’ landing is present, and an enclosed landing or a landing with steps and railings should exist beneath elevated exterior doors.

WINDOWS & DOORS: Bedrooms should be equipped with suitable egress (emergency escape or rescue) windows that are openable, at least 5.7 square feet in size, and no higher than 44 inches above the floor, and working locks are ideally present on bedroom and bathroom doors for privacy – excluding master bathrooms connected to master bedrooms. Windows should not be left open during periods of rain or snow to prevent damage to interior window stools or other materials, and doors should not open above steps unless a minimum 3’ x 3’ landing is present to prevent possible injury. Deadbolt locks ideally exist at exterior doors for added security, and deadbolts should be keyed only at the exterior. Openable doors and windows should operate smoothly, and window and door locks should be properly aligned and functional.

INTERIOR: Monitoring for new or worsening cracks in walls and ceilings, doors or windows that begin to stick, stains that may form on finishing materials, and other signs of damage that may arise at the interior should be common practice. Any such cracks or stains should be well sealed to make further damage that may arise more apparent. Shades/covers should be present at interior light fixtures to protect bulbs, closet lighting should be LED or fluorescent, and at least one receptacle outlet should exist in any hallways that are 10 ft or longer. Periodic monitoring for unwanted pest activity is also recommended, as well as maintaining the interior in a clean and sanitary condition. Cosmetic defects, such as carpet stains, scrapes, dings, markings and the like, do not generally affect safety or durability and are typical of nearly all houses to some extent, but cosmetic issues are ideally addressed for aesthetic purposes.

KITCHEN & BATHROOMS: All kitchen and bathroom caulk and grout will naturally deteriorate over time and should be continually monitored and cleaned, repaired or replaced as often as noticeably necessary – whether in poor condition now or in the future – to prevent moisture intrusion into concealed wall and floor areas that could lead to mostly hidden damage over time. Toilet closet bolts should also be kept tight and capped to prevent loosening and corrosion, adequate clearances should exist around toilets, and mechanical drain stoppers at tubs and sinks should be adjusted as needed to ensure proper function. Shower arms are also ideally surrounded by a waterproof material extending at least 3 inches above the flange to prevent possible moisture damage to walls, and carpet in kitchen and bathrooms should be kept clean or (preferably) replaced with a more water-resistant flooring material like tile, vinyl or linoleum. Cabinetry and counter or vanity tops should be well secured, upper cabinets should be secured with appropriate cabinet or pan head screws, and minor damage to kitchen or bathroom components should be addressed promptly to prevent further damage – especially from water.

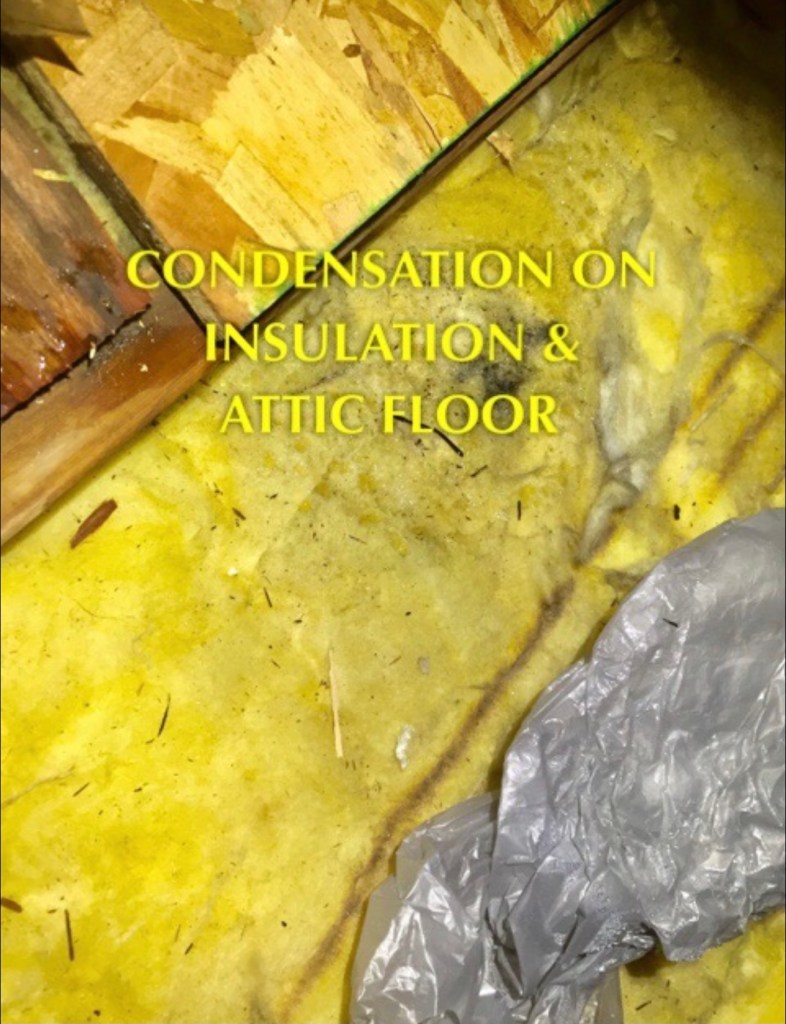

ATTIC, INSULATION & VENTILATION: The underside of the roof structure (rafters or trusses, planks or sheathing, etc) in unfinished attic spaces should be periodically monitored for signs of possible leaking, excessive condensation buildup, microbial growth or other damage, and insulation should also be monitored. Attics in this climate zone (the Northeast) ideally contain insulation levels equivalent to R-30 to R-38 or higher, and unfinished attic access doors, hatches or panels should be sufficiently sized, well sealed and insulated. All roof framing members should be intact and well fastened, and horizontal collar ties should exist along the upper third of rafters for gable (triangular shaped) roofs in order to stabilize the roof structure – especially against wind uplift forces. Monitoring for pest activity (especially rodents) is also advised, as attics are a common nesting area for unwanted invaders. Kitchens should contain mechanical ventilation, such as an above-range microwave or range hood, to filter cooking residue and expel warm, moisture-laden air, and bathrooms should contain an exhaust fan that terminates outdoors and/or openable window to expel moisture and noxious odors to the exterior. Dryer vents should be composed of metal (preferably smooth rigid metal) and should be routed to an unscreened baffled or louvered exterior exhaust hood (although indoor lint trap canisters may be sufficient for electric dryers). Lastly, attic bypasses should be well sealed – observing required clearances around lights or heat rated vents – to prevent unwanted air leakage and ensure optimal energy efficiency.

STRUCTURE: Any structural issues that may arise in the future should be addressed immediately by a qualified professional, and any planned alterations to the home’s structure should first be reviewed and approved by a qualified structural engineer or architect. While some degree of settlement and moisture intrusion is common (especially in below-grade space), measures should be taken to ensure that the structure is continually sound and that moisture levels are not excessive. Elevated moisture/humidity levels can lead to efflorescence, microbial growth (like mold) and eventual wood deterioration, and dehumidifiers should generally be used in this climate zone (especially in basements) to help control humidity levels. Ensuring that rim (band) joist cavities are well sealed and insulated will also help improve energy efficiency, and the paper facing (vapor barrier) of insulation batts should always face the conditioned portion of the home… “paper faces people.” Cracks in basement slabs (floors) are generally not a cause for alarm, but any open cracks should be sealed and periodically monitored, and thin cracks from settlement or shrinkage in structural masonry walls should be well sealed to prevent unwanted moisture intrusion.

PLUMBING: Visible supply and waste pipes, as well as valves, should be periodically monitored for signs of leaking or excessive corrosion/encrustation buildup. Some degree of corrosion is typical of metal piping and valves, and plastic piping that will not corrode offers several advantages over metal piping (like copper and cast iron), while modern ball valves are generally more reliable and user-friendly than older style gate valves. Faucet aerators should be present and periodically cleaned, and faucets, valve handles, sinks and other fixtures should be well secured. Water heating equipment should be equipped with an expansion tank on the cold-side inlet (especially with public water supplies) to prevent possible damage to plumbing as water heats and expands, and expansion tanks should be properly secured. Gas water heaters should be elevated at least 3 inches, and their vent connector (flue) should slope steadily upward at a minimum rate of 1/4-inch per linear foot and be well sealed at its entrance into any chimney. Although often missing, dielectric unions should exist at water heater connections to prevent corrosion from an ion exchange between dissimilar metals, and at least 18 inches of rigid supply piping (typically copper) should exist directly above water heaters prior to attaching to plastic, like PEX tubing or CPVC. Older style S and drum traps are very common beneath sinks, but they can siphon out the water seal necessary to prevent sewer gases from re-entering the interior and are ideally replaced with modern P traps – especially if the water seal is frequently siphoned out. Likewise, flexible accordion style drain lines are often used for their ease of installation, but rigid plastic drain piping (typically PVC) is preferred.

ELECTRICAL: All electrical work should be completed by a qualified electrician, as electricity poses a safety risk (including even death in some cases) to untrained individuals. Ensure that smoke and carbon monoxide (CO) detectors are always located on each floor, in each bedroom, near all sources of combustion, and periodically tested for safety. It is also recommended that any GFCI receptacles be tested monthly with their onboard test and reset buttons, and GFCI protection ideally exists in bathrooms, kitchens, garages, outdoors, in basements and crawlspaces, and within 6 feet of any sink or water source. All junction boxes, receptacle outlets and switches should be covered, and faceplates should be intact and free of cracks or other damage. Older two-prong outlets (while typically “grandfathered in” with old homes) are ideally upgraded to modern three-prong grounded outlets for safety, and all outlets should be properly wired with correct voltage and firmly secured in walls, floors or ceilings. Generally speaking, branch circuit wires in electrical panels should each be secured under their own lug (screw) and not “double tapped,” and all wires should be appropriately sized or larger than required for their corresponding breakers or fuses. While not inherently defective, any older fuses are ideally upgraded to modern circuit breakers that are more user-friendly, and corroded electrical equipment that may be prone to increased resistance should be repaired or replaced, depending on the severity of buildup. Outdoor wiring should be adequately protected (typically in conduit and/or by being buried) and rated for outdoor use, and all wiring should be well secured – including within 12 inches of electrical panels. Panel legends should also be fully labeled, breakers should be designed for the panel and the same brand, and all panel cover screws should be present. Electrical panels should be readily accessible and unobstructed, and clearances of at least 36 inches in front of panels and 30 inches across their front should exist. Any incandescent bulbs that may exist would ideally be replaced with modern, more efficient LED bulbs; and any bulbs listed as not working that do not work after being replaced should be evaluated further by a qualified electrician.

HVAC: Generally speaking, heating and cooling systems should be checked, cleaned and serviced (“tuned”) every year by a qualified HVAC technician or plumber, depending on the type of system. Filters serving forced air systems should also be properly cleaned or changed on a frequent basis to promote proper airflow, optimal system performance and good indoor air quality, and dark streaks from thermal bridging (“ghosting”) may appear along walls or ceilings when dirty air particles combine with vapor and settle along cool surfaces. Despite its name, duct tape is not intended for use with ductwork, and any duct tape that may exist at duct joints would best be replaced with foil tape, mastic or another suitable sealant. If present, A/C suction lines should be thoroughly insulated with the insulation maintained in a good state of repair, and at least 12 inches of clear space should exist around outdoor condensing units with a minimum clearance of at least 3 ft directly above. Budgeting to replace A/C systems equipped with older R-22 refrigerant (Freon) is strongly recommended, as R-22 is now prohibited, and such systems sometimes require full replacement when problems arise. Heating systems requiring combustion air should exist in spaces with ample air volume or louvered openings, and any intake or exhaust vents should be screened at the exterior. Intakes for high-efficiency systems should also be run to the exterior, rather than open to basements or other interior spaces, as this can cause a buildup of negative air pressure indoors. While not required, older mechanical thermostats are best upgraded to programmable thermostats – preferably modern “SMART” models that can be controlled remotely and track data related to usage habits – to noticeably reduce energy consumption and save cost.

A FINAL WORD: While this guide covers a great deal of information and is intended to help homeowners gain knowledge and formulate a plan that is suitable to their own homes, every house is unique and will occasionally require the skill and expertise of qualified and experienced contractors. Knowing when to “DIY” (do-it-yourself) a project versus when to call in a pro is an important distinction, and no task should be tackled without confidence, careful planning and a focus on safety.

*To visit our main website, go to: http://www.hillinspections.com